The project

Shinfox Far East (SFE) commissioned TWD to design a pin pile lifting tool (PPLT) and a jacket flange lifting tool (JFLT) for the TPC Offshore Wind Farm off the coast of Taiwan. The PPLT’s primary function is to lift pin piles for installing jackets, which serve as foundations for offshore wind turbine generators.

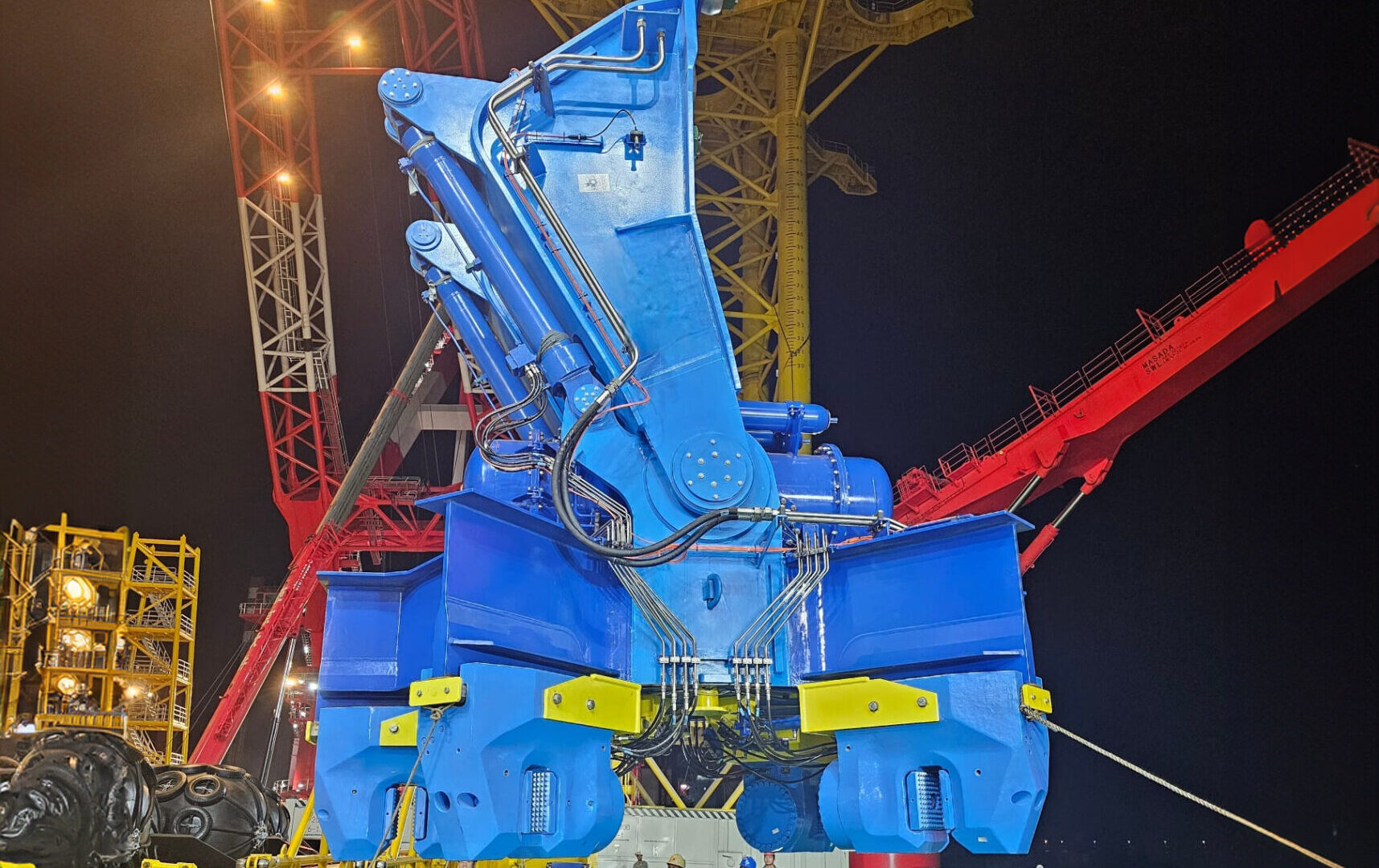

The PPLT is designed to lift and upend the pin pile by securing itself with hydraulic clamps. It includes a stabbing frame to ensure a smooth landing on the pin pile and has a working load limit of 800 tons.

The JFLT is specifically engineered to lift jackets, which are foundational structures for offshore wind turbine generators and can also be used to lift the piling template for the pinpiles.

The JFLT design features three rotating clamps that securely attach under the jackets flange serving as the lifting interface. These clamps are self-locking, significantly reducing operational risks. The clamps are connected to a Y-shaped spreader beam, which is equipped with a tugger frame for precise rotation and a catcher for accurate placement.

Our Approach

Hydrauvision designed and delivered the complete drives and controls for both tools.

This included:

- A submergible valve box, which is located on top of the PPLT and controls the hydraulic clamps. It contains manifolds, welded in the side with the control valves, an external piston accumulator for energy storage, a PLC for the control system and a CCTV system.

- A PPLT Support module which is an intermediate point for the hydraulic hoses from the umbilical winch. It contains the batteries for the control system and cameras, an E-cabinet and piping for connection from the umbilical winch to the PPLT. This box stays above the seawater.

- A JFLT Support module, which contains batteries, an E-cabinet with controls and a hydraulic power pack.

- A Local Operated Panel (LOP) for operating both tools.

We also delivered a 55 kW electric driven offshore certified hydraulic power unit and the umbilical winch which supplies the PPLT with hydraulics. Our Offshore Certified Service Engineers were on site in Asia to assist during assembly and commissioning.